30 ohm resistor is a key component in many electronic circuits. Resistors use to regulate the current flow in a circuit, ensuring that other components, such as LEDs, microcontrollers, and transistors, receive the correct voltage. Whether you're building a circuit for a hobby project or working on a more complex design, understanding the specifications and applications of resistors like the 30 ohms variety is necessary. This guide covers everything you need to know about 30-ohm, including their types, colour codes, power ratings, and common uses.

5. Common Applications of 30 Ohm Resistors

6. Frequently Asked Questions [FAQ] About 30 Ohms Resistor

What is a 30 Ohm Resistor?

30-ohm is a type of passive electronic component that limits the amount of current that flows through a circuit. Resistances measure in ohms (Ω), and it specifically provides 30 ohms of resistance. 30Ω helps to prevent overcurrent, which will damage sensitive components. These resistors come in various forms, with different materials, power ratings, and tolerances suited for different applications.

Types of Resistor 30 Ohm

Several types, each design for different uses:

30 Ohm Ceramic Resistor

Widely use in high-temperature applications. Make from ceramic materials and offer excellent thermal stability. These resistors are ideal for circuits requiring high resistance and can withstand power surges.

Wire Wound

Wire-wound make by winding a metal wire (usually nickel-chromium or copper-nickel) around a ceramic or fiberglass core. These resistors are highly accurate, reliable, and suitable for high-power applications. They commonly use in power supplies and audio equipment.

30 Ohm Braking Resistor

Use in systems like electric motors to dissipate energy generated during braking. A 30-ohm braking resistor with a wattage rating of 1 kW commonly use in motor control systems.

30 Ohm Power Resistor

Design to dissipate significant amounts of power without overheating. Have larger bodies and higher wattage ratings. Use in high-current applications, such as power supplies or power conversion systems.

30 Ohm Metal Oxide Film Resistors

Make by applying a metal-oxide-film onto a ceramic core. They provide stable resistance and are generally more durable than carbon-based resistors. Metal oxide film type often use in power-sensitive applications.

Metal Film

Similar to metal oxide but are known for their precise resistance values. Metal film type offer low noise and excellent stability. They are ideal for applications requiring high precision, such as signal processing.

Carbon Film

Made by applying a thin layer of carbon to a ceramic base, carbon-film are inexpensive and offer moderate accuracy. Suitable for general-purpose applications, such as consumer electronics and small electronics projects.

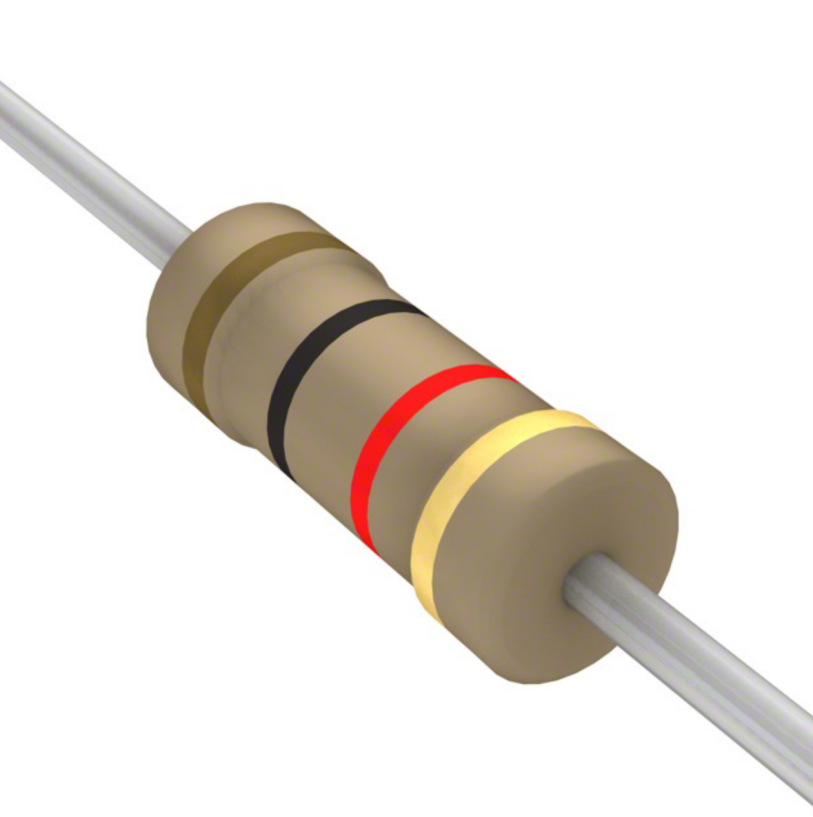

30 Ohm Resistor Color Code

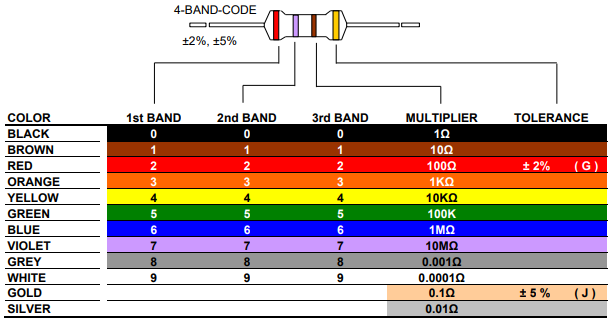

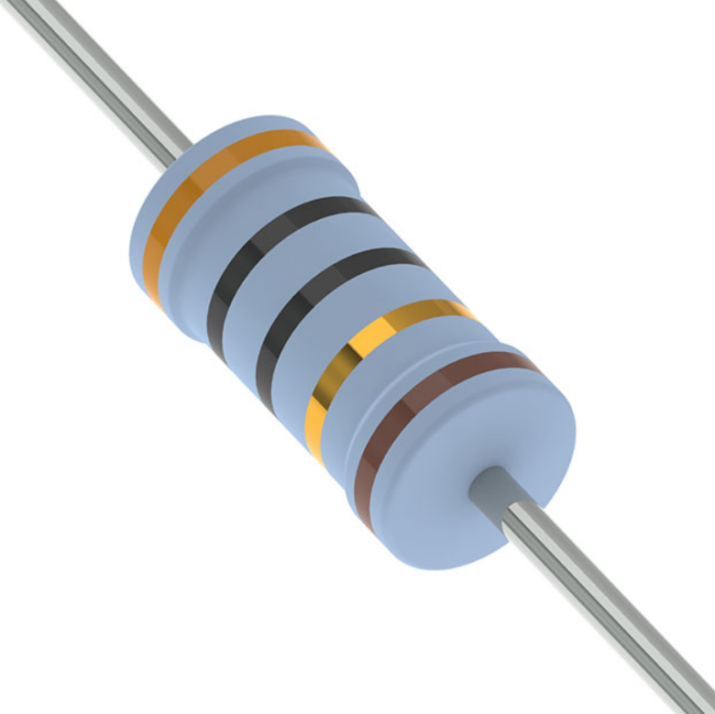

Use the colour codes to indicate 30-ohm’s resistance value, tolerance, and sometimes its temperature coefficient(6-band-resistor). For a 30-ohm 4-band colors are:

Band | Colour | Meaning |

1st | Orange | 3 (First-digit) |

2nd | Black | 0 (Second-digit) |

3rd | Black | ×1 (Multiplier) |

4th | Gold | ±5% (Tolerance) |

Breakdown:

· Orange (3): The first-digit is 3.

· Black (0): The second-digit is 0.

· Black (×1): The multiplier is 1 (no change to the base value).

· Gold (±5%): The tolerance is ±5%, which means the actual resistance vary by 5% above or below 30-ohms.

So, the final resistance is 30 ohms with a ±5% tolerance.

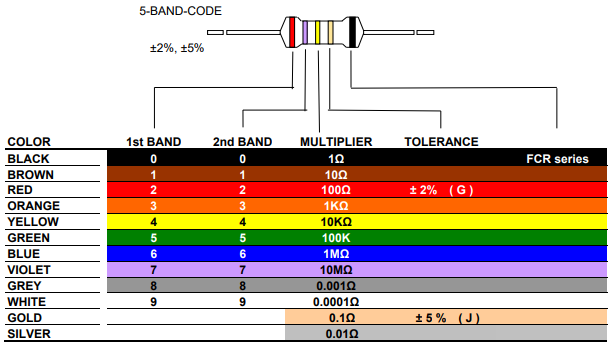

For a 30-ohm 5-band colors are:

Band | Colour | Meaning |

1st | Orange | 3 (First-digit) |

2nd | Black | 0 (Second-digit) |

3rd | Black | 0 (Third-digit) |

4th | Gold | ×0.1 (Multiplier) |

5th | Brown | ±1% (Tolerance) |

Breakdown:

· Orange (3): The first-digit is 3.

· Black (0): The second-digit is 0.

· Black (0): The third-digit is also 0.

· Gold (×0.1): The multiplier, meaning the value of the first three digits (300) multiply by 0.1, resulting in 30 ohms.

· Brown (±1%): The tolerance is ±1%, meaning the actual resistance can vary by 1% above or below 30-ohms.

So, the final value is 30 ohms with a ±1% tolerance.

The difference between the 4-band and 5-band 30-ohm is mainly in their tolerance and precision. Both represent 30 ohms, but the 4-band is less precise (±5%) while the 5-band is more accurate (±1%) and better suited for precision electronic applications.

Power Rating and Tolerance

30 Ohm 1/4 Watt Resistor

Use in low-power circuits such as LED circuits and signal processing. Suitable for applications with minimal current and voltage, ensuring no excess heat.

30 Ohm 1/2 Watt Resistor

Common in audio equipment, voltage dividers, and general-purpose applications where require moderate power dissipation.

30 Ohm 1 Watt Resistor

Ideal for power supplies, braking resistors, and consumer electronics where current is higher but power dissipation is moderate.

2W 30 Ohm Resistor

Use in high-power LED circuits, power conversion, and pulse circuits needing more heat dissipation than lower-rated resistors.

30-Ohm 5 Watt

Use in electric motor controllers, power resistors, and audio amplifiers where higher currents are involved and significant heat dissipation is necessary.

30-Ohm 10 Watt

Found in high-power LED drivers, heavy-duty power supplies, and braking systems for industrial motors.

30 Ohms 20 Watt

Use in large motor systems, high-power electronic circuits, and energy dissipation applications requiring robust power handling.

30 Ohms 25 Watt

Common in power regulation systems, large electric motor control, and high-current circuits that require higher heat tolerance.

30-Ohms 30 Watt

Use in industrial power systems, motor control, and high-current circuits, providing significant heat dissipation and stability.

30 Ohm 50 Watt

Applied in large power systems, electric motors, and inverters where high power and energy dissipation are essential for safety and performance.

Resistor 30 Ohm 480 Watt and 500 W

Found in industrial motor control, energy-intensive applications, and large power management systems that need to dissipate substantial energy.

Tolerance

Defines how much the actual resistance can vary from the nominal value. Common tolerance values for 30-ohm include:

· ±0.005%, ±0.01%, ±0.02%, ±0.05%, ±0.1%, ±0.25%, ±0.5%, ±1%, ±2%, ±5%, ±10%

The lower tolerance percentage, the more precise of resistor’s value.

Common Applications of 30 Ohm Resistors

30 Ω commonly use in the following application:

LED with a 30 Ohm Resistor: Use in LED circuits to limit the current and prevent damage to the LEDs. This helps in achieving the right brightness without overloading the LED.

Power Supply Circuits: With a variety of power ratings, 30-ohm can regulate current in power supply circuits, ensuring that components such as capacitors and transistors receive the appropriate voltage.

Audio Equipment: As their precision, 30 ohms also use in audio systems to control the signal flow and prevent distortion.

Motor Control: In systems such as electric-braking systems, 30 ohm braking-resistors use to dissipate the energy generated during braking, maintaining safety and performance.

Frequently Asked Questions [FAQ] About 30 Ohms Resistor

What is the power of the 30 ohm resistor?

The powers of a 30-ohm depends on its wattage rating, which indicates how much heat it can safely dissipate. Common ratings include 1/4W, 1/2W, 1W, 2W, 5W, 10W, and higher for industrial applications. Choosing the correct power rating ensures the resistor can handle the current flowing through it without overheating or burning out. The higher the wattage, the more power it can safely manage in the circuit.

What is the color code for a 30 ohm resistor?

The colors coding for 30 ohms resistors depends on its band configuration. For a 4-band type, the code is Orange-Black-Black-Gold, which represents 30 ohms with ±5% tolerance. For a 5-band coding, it is Orange-Black-Black-Gold-Brown, representing 30-ohms with ±1% tolerance. The colors indicate the digits, multiplier, and tolerance, allowing users to identify resistance values quickly and accurately without needing to measure them with tools.

What does a 30 ohm resistor do?

A 30-ohm limits the flow of electric current in a circuit, helping to protect sensitive components from excessive current. It drops voltage across its terminals, controlling power distribution and maintaining circuit stability. In LED circuits, it regulates brightness and prevents damage. In power systems, it ensures safe operation by managing current flow. Essentially, it converts excess electrical energy into heat, maintaining the circuit’s proper performance and reliability.

What happens if I use the wrong resistor?

Using the wrong resistor value can lead to circuit malfunction or damage. If the resistance is too low, excessive current flow, potentially overheating components or causing failure. If it’s too high, the circuit receive insufficient current, leading to weak performance or no operation. Using a resistor with an incorrect power rating can also result in overheating or burning. Selecting the right resistance and wattage ensures safe, efficient, and stable circuit operation.

What happens if the resistor is backwards?

Can place a resistor in either direction because it is a non-polarized component. Its electrical behavior remains the same regardless of orientation. Unlike diodes or electrolytic capacitors, resistors do not have a positive or negative side. However, when using color-coded resistors, it’s best to align them consistently for easy reading and circuit inspection. Functionally, a resistor installed backwards will work exactly the same and will not affect circuit performance.

Can I use a multimeter to check a resistor?

Yes, you can use a multimeter to measure the resistance of a resistor. Set the multimeter to the resistance (Ω) mode, connect the probes to each resistor lead, and read the displayed value. This helps verify if the resistor matches its rated resistance or has drifted as age or damage. For accurate results, remove the resistor from the circuit before testing, as connected components can affect the reading and lead to inaccurate results.

Conclusion

Understanding the different types, specifications, and applications of the 30 ohm resistor is necessary for building effective and efficient electronic circuits. Whether you're using it in a simple LED circuit or in a complex power system, the circuit plays a key role in ensuring the proper functioning of your design. With the right power rating, tolerance, and material, you can select the perfect 30-ohm for your project needs.

Read More:

1. Guide to the 3 Ohm Resistor: Specifications and Color Code

HOT NEWS

The 0402 Resistor: A Comprehensive Guide

0402 Resistor

2025-05-06

Understanding A 0603 Resistor

0603 resistor,dimensions,marking code, values

2025-05-29

What Is A 1206 Resistor?

1206 resistor dimensions,footprint,value

2025-06-05

What is 10k Ohm Resistor?

10k resistor 10k resistor color code

2025-05-14

Everything You Need To Know About ARE1309 Relay

2025-04-23

MT3608 Boost Converter - An In-Depth Guide

MT3608 Boost Converter

2025-09-04

What Is The 1K Ohm Resistor?

1k ohm resistor and color code

2025-05-21

Guide To The AMS1117 Voltage Regulator

AMS1117 Voltage Regulator Circuit

2025-08-17

2512 Resistor - A Comprehensive Guide

2512 Resistor

2025-08-13

What is 100 Ohm Resistor And Color Code?

100 ohm resistor color code

2025-05-17

Product Catalog

Product Catalog