Variable resistor is widely used electronic components that allow users or circuits to adjust resistance values as needed. Unlike fixed resistors, they offer flexibility in controlling current, voltage, and signal levels. From volume controls to sensor circuits, variable resistors play a key role in both analog and digital electronics.

1. What is a Variable Resistor?

3. Structure and Working Principle

5. Physical Characteristics and Specification

8. Advantages and Limitations of Variable Resistors

9. Potentiometer vs Variable Resistor

10. Frequently Asked Questions

What is a Variable Resistor?

A variable resistor is an electronic component whose resistance value can adjust to control current or voltage within a circuit. Unlike fixed resistors, it allows flexibility by enabling manual, mechanical, or electronic adjustment. Variable resistors work by changing the effective length of a resistive element using a movable contact called a wiper. They commonly use for volume controls, light dimmers, motor speed regulation, and circuit calibration. Depending on how they connect, these resistors can function as current limiters or voltage dividers, making them widely used in analog and digital electronic applications.

Variable Resistor Symbol

In circuit diagrams, it representes by:

A zigzag line (or rectangle) indicating resistance

An arrow or diagonal line crossing the resistor, representing adjustability

Common symbols include:

Variable resistor (two-terminals)

Potentiometer (three-terminals)

Rheostat (two-terminals, often derived from a potentiometer)

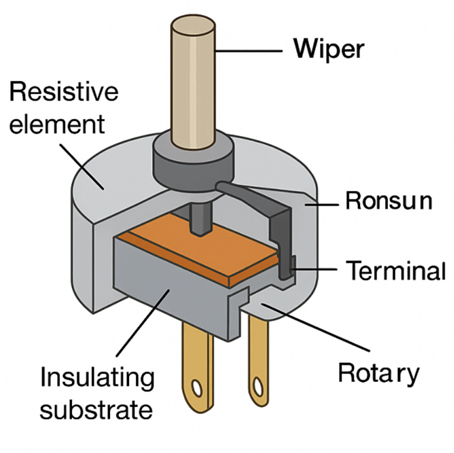

Structure and Working Principle

Variable resistor is an electronic component designed to provide adjustable resistance in a circuit. Its structure consists of a resistive element, a movable contact called a wiper, terminals, and a protective housing. The resistive element can make from carbon, cermet, conductive plastic, or wire-wound materials, chosen based on precision, power handling, and durability. This element mounte on an insulating substrate to provide mechanical support and electrical isolation.

The wiper moves along the resistive element, either through a rotary knob, shaft, or linear slider. Its position determines the effective length of the resistive path, thereby controlling the resistance between terminals. Variable resistors typically have two or three terminals. A two-terminal configuration, called a rheostat, adjusts current directly, while a three-terminal configuration, called a potentiometer, acts as a voltage divider to provide variable voltage output.

The working principle is simple: as the wiper moves along the resistive track, the effective resistance changes. Increasing the distance between the wiper and a terminal increases resistance, reducing current or voltage. Decreasing the distance lowers resistance, allowing higher current or voltage.

These resistors widely use for current regulation, voltage division, calibration, and signal adjustment in circuits. The combination of the resistive element, wiper, and terminals allows smooth, precise, and reliable resistance control in both analog and digital electronics.

Types of Variable Resistor

These resistors come in several types, each suited for specific applications depending on power, precision, and adjustment method.

Potentiometer: A three-terminal device used mainly as a voltage divider. It provides adjustable voltage output and commonly use in audio controls, instrumentation, and calibration circuits.

Rheostat: A two-terminal resistor designed to control current directly. It often use in high-power applications such as motor speed regulation and light dimmers.

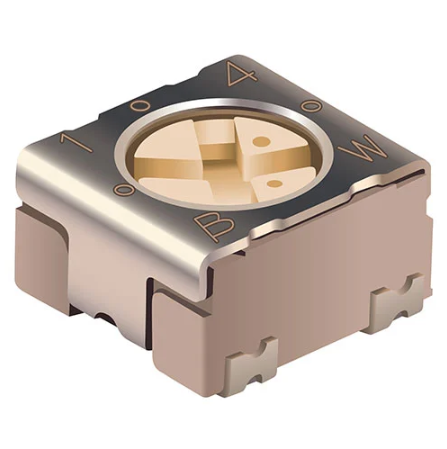

Preset or Trimmer Resistor: Small, compact resistors used for circuit calibration. They adjuste infrequently using a screwdriver and are ideal for fine-tuning electronic circuits.

Digital Variable Resistor: Electronically controlled resistors using digital signals. These allow precise resistance adjustment via microcontrollers or digital circuits and use in modern electronics and automated systems.

Photoresistor (LDR): A light-dependent resistor whose resistance decreases with increasing light intensity. It widely use in light-sensing applications like automatic lighting and alarms.

Thermistor: A temperature-dependent resistor. NTC (negative temperature coefficient) decreases resistance with rising temperature, while PTC (positive temperature coefficient) increases resistance. Commonly used in temperature sensing and protection circuits.

Film-Type Variable Resistors: Made from carbon or cermet films, providing smooth resistance variation, low noise, and compact size. Ideal for general-purpose control applications.

Wire-Wound Variable Resistors: Use resistive wire wound on a core, capable of handling high power. These resistors are durable but have discrete steps in resistance.

Rotary Variable Resistors: Adjusted by rotating a knob or shaft. Most common form of potentiometer or rheostat, used in volume controls, tuning circuits, and adjustable power supplies.

Each type of the resistor design to meet specific power, precision, and control requirements, making them versatile components in electronic circuits.

Physical Characteristics and Specification

Have several physical characteristics and specifications that define their performance and suitability for different applications. Understanding these helps in selecting the right component for a circuit.

Resistance Value: Indicates the total resistance range the resistor can provide, typically expressed in ohms (Ω), kilo-ohms (kΩ), or mega-ohms (MΩ). Common values include 1kΩ, 10kΩ, 100kΩ, and higher.

Tolerance: Specifies the allowable deviation from the nominal resistance, usually ±5%, ±10%, or ±20%. Higher precision applications require lower tolerance components.

Power Rating: Indicates the maximum power the resistor can safely dissipate without damage, measured in watts (W). Common ratings range from 0.1W for small trimmers to several watts for wire-wound rheostats.

Adjustment Type: Determines how resistance change, typically rotary (rotating knob or shaft) or linear (sliding control). Some multi-turn potentiometers provide finer adjustment.

Number of Turns: Single-turn potentiometers adjust resistance in one complete rotation, while multi-turn types allow gradual and precise changes over multiple rotations.

Temperature Coefficient: Represents how resistance changes with temperature, important for stability in sensitive circuits.

Mounting Type: Can be panel-mounted for user access or PCB-mounted for circuit board integration. Surface-mount devices (SMD) are available for compact electronic designs.

Size and Shape: Varies from small trimmer resistors for calibration to larger wire-wound rheostats for high-power applications.

Material Type: Resistive element is carbon, cermet, conductive plastic, or wire-wound, affecting durability, smoothness, and noise characteristics.

By considering these characteristics—resistance range, tolerance, power rating, adjustment method, temperature stability, mounting style, and material—designers can select the appropriate resistor to ensure reliable performance in their specific electronic application.

Specification | Typical Values / Notes |

Resistance Value | 10Ω – 10MΩ (common: 1k, 10k, 100k) |

Tolerance | ±1%, ±5%, ±10%, ±20% |

Power Rating | 0.1W – 10W (trimmers low, wire-wound high) |

Adjustment Type | Rotary, Linear, Multi-turn |

Number of Turns | Single-turn, Multi-turn (2–10 turns) |

Temperature Coefficient | 50 – 500 ppm/°C (depends on material) |

Mounting Type | PCB-mount, Panel-mount, Surface-mount (SMD) |

Size / Dimensions | Small trimmers (3–6mm) to large wire-wound types (50–100mm) |

Resistive Material | Carbon, Cermet, Conductive Plastic, Wire-wound |

Number of Terminals | 2 (rheostat) or 3 (potentiometer) |

Operating Temperature Range | -40°C to +125°C (typical) |

Linearity / Taper | Linear or Logarithmic (audio taper) |

Mechanical Life | 5,000 – 50,000 operations (depends on type) |

Electrical Life | 1,000 – 10,000 cycles (depends on load and material) |

Noise Level | Low noise for carbon/cermet, minimal in conductive plastic |

Resolution / Minimum Step | Especially for multi-turn types, can be 0.1% of total resistance |

Environmental Resistance | Moisture, dust, and vibration resistance (varies by housing type) |

Inductance / Capacitance | Minimal in film types, higher in wire-wound at high frequency |

Maximum Voltage Rating | Typically 50V – 500V depending on design |

Application Type | Audio control, motor control, calibration, sensor interface |

Functions and Applications

Primary Functions:

Current Control: Can limit or regulate current in a circuit, protecting components from excessive flow.

Voltage Adjustment: When configured as a potentiometer, they act as voltage dividers, providing variable output voltage.

Signal Conditioning: Used to fine-tune signals in audio, instrumentation, and communication circuits.

Calibration and Tuning: Enable precise adjustment of circuits for optimal performance during setup or maintenance.

Sensing Environmental Changes: Special types like photoresistors and thermistors change resistance based on light or temperature, enabling sensor applications.

Common Applications:

Audio Controls: Volume, tone, and balance adjustment in audio equipment.

Lighting Systems: Dimming lights in residential or industrial applications.

Motor Speed Control: Adjusting the speed of DC motors in appliances, robotics, and industrial machines.

Power Supplies: Voltage regulation and fine-tuning output in adjustable power circuits.

Sensor Circuits: Light detection using LDRs, temperature measurement with thermistors, or environmental monitoring.

Calibration Devices: Trimmers and presets in measurement instruments and electronic boards.

User Interfaces: Control panels for electronic equipment where require adjustable settings.

Application Table

Application Type | Recommended Variable Resistor |

Audio control (volume, tone, gain) | Carbon or cermet potentiometer, Precision potentiometer |

Motor and lighting control | Wire-wound rheostat, Rotary or slider potentiometer |

Circuit calibration and instrumentation | Trimmer / Preset resistor, Multi-turn precision potentiometer |

Microcontroller and automated systems | Digital variable resistor |

Sensor-based applications (light, temperature) | Photoresistor (LDR), Thermistor |

Adjustable power supplies | Wire-wound rheostat, Multi-turn potentiometer |

Home appliances and industrial equipment | Wire-wound or rotary potentiometer |

Potentiometers in Detail

Potentiometers are a widely used type of variable resistor that allow adjustable voltage or signal control. They commonly employ in audio equipment, calibration circuits, lighting controls, and electronic instrumentation. Potentiometers offer precise, manual control over resistance and can use either as a voltage divider or, in some cases, as a rheostat.

Types of Potentiometers

By Material:

Carbon Potentiometers are the most common type, offering low cost, general-purpose use, and moderate durability. Cermet Potentiometers make from ceramic and metal, providing higher precision and stability, ideal for instrumentation. Conductive Plastic Potentiometers offer smooth operation, low noise, and long mechanical life. Wire-Wound Potentiometers handle high power and use in industrial applications or high-current circuits.

By Design:

Rotary Potentiometers adjust by turning a knob or shaft and widely use in audio controls and tuning devices. Linear (Slider) Potentiometers adjust by moving a slider along a straight path, commonly seen in mixing consoles and control panels. Multi-Turn Potentiometers allow fine, precise adjustments by multiple rotations of the wiper, making them ideal for calibration and measurement circuits.

Advanced Types:

Digital Potentiometers provide electronically controlled resistance using digital signals, compatible with microcontrollers and automated systems. Motorized Potentiometers can adjust automatically via a motor, useful in audio automation or remote control systems. Logarithmic Potentiometers (Audio Taper) change resistance logarithmically for audio applications, matching human hearing perception.

Using Potentiometers

Potentiometers can be applied in several ways. When used as a voltage divider, connect all three terminals, and the wiper provides a variable voltage proportional to its position. When used as a rheostat, two terminals (one end and the wiper) control current flow in a circuit. Potentiometers also use for circuit calibration, where trimmers and multi-turn types fine-tune circuits during setup or maintenance. Additionally, they use for signal adjustment, including volume, tone, and gain control in audio and instrumentation circuits.

Potentiometers combine flexibility, precision, and durability, making them essential components in both consumer and industrial electronics.

Common Potentiometer Resistance Codes

Potentiometers often marked with resistance codes that indicate their nominal resistance value. These codes follow a standardized notation similar to fixed resistors. Understanding these codes helps select the correct potentiometer for a circuit.

By understanding these resistance codes, users can easily choose the right potentiometer for applications like volume controls, sensor interfaces, calibration circuits, and adjustable power supplies.

Resistance Code | Resistance Value |

102 | 1,000 Ω (1kΩ) |

103 | 10,000 Ω (10kΩ) |

104 | 100,000 Ω (100kΩ) |

105 | 1,000,000Ω (1MΩ) |

202 | 2,000 Ω (2kΩ) |

203 | 20,000 Ω (20kΩ) |

502 | 5,000 Ω (5kΩ) |

503 | 50,000 Ω (50kΩ) |

503 | 50,000 Ω (50kΩ) |

223 | 220,000 Ω (220kΩ) |

104 | 100,000 Ω (100kΩ) |

473 | 47,000 Ω (47kΩ) |

Advantages and Limitations of Variable Resistors

Advantages of Variable Resistors:

Offer adjustable control over current and voltage in a circuit, making them highly versatile. They allow fine-tuning and calibration of electronic devices for optimal performance. They can act as voltage dividers or rheostats, providing flexibility in various applications. Special types like photoresistors and thermistors can respond to environmental changes, enabling automatic control based on light or temperature. They are generally compact and easy to use, with options for rotary, linear, and digital adjustment. Multi-turn types provide high precision, and wire-wound versions can handle high power and offer durability.

Limitations of Variable Resistors:

These resistors have limited power ratings, so exceeding their capacity can cause overheating or damage. They generate electrical noise, especially carbon-based types, affecting sensitive circuits. Their mechanical life is finite, as repeated adjustments can wear out the resistive element or wiper. Environmental factors like dust, moisture, and vibration can reduce reliability. Wire-wound types may have discrete steps instead of smooth adjustment, and some digital variable resistors require additional circuitry for operation. Additionally, their size and cost can be higher than fixed resistors, particularly for precision or high-power types.

Potentiometer vs Variable Resistor

Feature | Potentiometer | Variable Resistor |

Number of Terminals | 3 | 2 or 3 |

Main Function | Voltage divider | Current or voltage control |

Connection Type | Divider configuration | Series configuration |

Adjustment Method | Rotary or sliding | Rotary, sliding, or digital |

Common Applications | Audio, controls | Power control, tuning |

Alternate Name | Pot | Rheostat (in 2-terminal use) |

Output | Variable voltage | Variable resistance |

Frequently Asked Questions

What is a variable resistor used for?

Use a variable resistor to adjust current or voltage in electronic circuits. It allows fine-tuning, calibration, and control of electrical signals. Common applications include volume controls, light dimmers, motor speed regulation, sensor circuits, and circuit calibration. Special types, like photoresistors and thermistors, can also respond to environmental changes such as light or temperature, providing automated control.

How do variable resistors work?

Variable resistors work by changing the effective resistance between terminals. A movable contact called a wiper slides or rotates along a resistive element. As the wiper moves, the resistance between terminals increases or decreases, which in turn controls current flow or voltage output. Depending on the configuration, it can function as a rheostat (current control) or potentiometer (voltage divider).

What are three common types of variable resistors?

Three common types are potentiometers, rheostats, and trimmer (preset) resistors. Potentiometers are typically three-terminal devices used as voltage dividers. Rheostats are two-terminal resistors used for controlling current. Trimmers or preset resistors are small, adjustable resistors for fine-tuning circuits, usually calibrated during setup and adjusted infrequently.

What is the main purpose of a variable resistor in a circuit?

The main purpose is to control electrical parameters by adjusting resistance. It can limit current, divide voltage, or fine-tune signals. These resistors allow circuits to be flexible and adaptable, enabling precise operation in audio equipment, sensors, motor controllers, and measurement instruments. They are essential for calibration, user control, and performance optimization.

How do you identify a variable resistor in a circuit diagram?

In circuit diagrams, represent by a resistor symbol with a diagonal arrow across it. The arrow indicates adjustability. For a potentiometer, the arrow points to the wiper terminal (middle terminal), while for a rheostat, it connects to the resistive element to indicate variable resistance between two terminals.

Can a variable resistor be used as a voltage divider?

Yes, a variable resistor can function as a voltage divider when use all three terminals of a potentiometer. The wiper terminal provides a voltage output proportional to its position along the resistive element. This allows smooth adjustment of voltage for applications such as signal control, calibration, and audio equipment.

What factors affect the lifespan of a variable resistor?

The lifespan depends on mechanical wear, power rating, temperature, environmental conditions, and usage frequency. Frequent adjustment can wear out the wiper or resistive element. Exceeding the power rating generates heat, reducing durability. Dust, moisture, or vibration can also impair operation. Material type and quality significantly influence long-term reliability.

Why are wire-wound variable resistors used in high-power circuits?

Use wire-wound variable resistors because they can handle high currents and dissipate heat efficiently. The resistive wire has high thermal stability and durability, allowing precise control in high-power applications like motors, industrial equipment, and power supplies. They also offer greater mechanical strength and longer life compared to carbon or cermet types.

What happens if a variable resistor exceeds its power rating?

Exceeding the power rating can cause the resistive element to overheat, potentially burning or damaging it. This can lead to permanent resistance changes, mechanical deformation, or complete failure. In some cases, it also generate smoke or fire, depending on the design. Always select a resistor with an adequate power rating for safety and reliability.

How can temperature affect the resistance of a variable resistor?

Temperature changes can cause the resistive element to expand or contract, altering its resistance. Materials like carbon or wire-wound have specific temperature coefficients, meaning resistance increase or decrease with temperature. Extreme heat can damage the element, while cold can reduce conductivity. Temperature effects must consider in precision circuits or high-power applications.

Conclusion

Variable resistors provide flexibility, control, and adaptability in electronic circuits. With multiple types available—from simple potentiometers to advanced digital variable resistors—they serve a wide range of applications across consumer electronics, industrial systems, and instrumentation. Selecting the right type depends on resistance value, power rating, precision needs, and environmental conditions.

Read More:

1. 1M Ohm Resistor - Color Code, Tolerance and Applications

2. 1000 Ohm Resistor Color Code and Applications

3. 47 Ohm Resistor: Color Code, Specifications and Applications

HOT NEWS

The 0402 Resistor: A Comprehensive Guide

0402 Resistor

2025-05-06

Understanding A 0603 Resistor

0603 resistor,dimensions,marking code, values

2025-05-29

What Is A 1206 Resistor?

1206 resistor dimensions,footprint,value

2025-06-05

MT3608 Boost Converter - An In-Depth Guide

MT3608 Boost Converter

2025-09-04

What is 10k Ohm Resistor?

10k resistor 10k resistor color code

2025-05-14

Everything You Need To Know About ARE1309 Relay

2025-04-23

What Is The 1K Ohm Resistor?

1k ohm resistor and color code

2025-05-21

2512 Resistor - A Comprehensive Guide

2512 Resistor

2025-08-13

Guide To The AMS1117 Voltage Regulator

AMS1117 Voltage Regulator Circuit

2025-08-17

What is 100 Ohm Resistor And Color Code?

100 ohm resistor color code

2025-05-17

Product Catalog

Product Catalog